Your Complete Resource to Choosing the Right Concrete Floor Coating

This guide will help you navigate the differences between Epoxy, Polyurea, and Polyaspartic coatings to make the best decision for your project—whether a residential garage or a commercial space.

In this guide, you’ll learn:

- The science behind each coating and how it affects performance.

- Common application mistakes and how to avoid them.

- Why our hybrid system might offer the best long-term value.

- How to properly maintain each coating to extend its lifespan.

Let’s dive right in.

Contents

1. The Challenge of Choosing the Right Concrete Coating

The type of floor coating you choose can make or break your project. But with so many coatings claiming to be the “best,” it’s hard to know where to begin. Epoxy, Polyurea, and Polyaspartic are the main options on the market, but each offers its own unique benefits and challenges.

Here’s a simple way to think about it:

- Epoxy: Exceptional adhesion and durability. Ideal as a base coat.

- Polyurea: Quick curing, flexible, but less adhesive.

- Polyaspartic: UV-resistant and fast-curing. Works best as a topcoat.

2. Understanding the Basics of Epoxy, Polyurea, and Polyaspartic Coatings

The Science Behind Epoxy, Polyurea, and Polyaspartic

Before you can choose the right coating, you need to understand the science behind each one. Let’s break it down in simple terms:

What is Epoxy?

The Adhesion Champion

Epoxy is a thermosetting polymer created when epoxide resin reacts with a hardener, forming an extremely durable material that bonds tightly to concrete.

- Key Strength: Deep penetration into the concrete for maximum adhesion.

- Best Use: Ideal as a base coat in high-durability projects like garages or industrial spaces.

What is Polyurea?

The Fast Option

Polyurea is a fast-curing elastomer. It’s often marketed for its quick application time—curing in just a few hours—but its downside is that it can’t match the adhesion of Epoxy.

- Key Strength: Fast curing and flexibility.

- Drawback: Weaker adhesion strength.

What is Polyaspartic?

The UV-Resistant Topcoat

Polyaspartic is essentially a type of polyurea with better UV resistance. This makes it ideal for areas exposed to sunlight and works well as a topcoat over epoxy.

- Key Strength: UV resistance and fast curing.

- Best Use: A topcoat to protect the underlying epoxy in outdoor or high-traffic spaces.

Environmental Impact:

Temperature, humidity, and UV exposure can significantly impact the curing process and the lifespan of each material. For instance, polyurea may not cure properly in high humidity, while epoxy performs better in stable conditions.

The Curing Process Explained:

Here’s how each material bonds with concrete:

- Epoxy: Longer curing time (24-48 hours) allows for deep penetration and adhesion to the substrate.

- Polyurea: Cures rapidly (1-2 hours), but the quick set time can lead to a weaker bond with the concrete.

- Polyaspartic: Cures in 2-4 hours and provides a durable top layer with excellent UV resistance.

3. Epoxy: The Foundation of a Strong Concrete Floor

Epoxy coatings are widely regarded as the most reliable base coat for concrete floors. It’s the go-to choice when you need long-term durability and strong adhesion.

Why Choose Epoxy?

- Superior Adhesion: Epoxy penetrates concrete deeply, forming a bond that ensures your floor coating won’t peel or delaminate.

- Unmatched Durability: It can handle heavy traffic, impacts, and exposure to chemicals, making it perfect for garages, industrial floors, and commercial spaces.

- Cost-Effective: Epoxy provides long-lasting protection at a lower cost than polyurea or polyaspartic.

Technical Depth: Compressive Strength

Epoxy’s compressive strength can exceed 10,000 psi, making it ideal for areas that require extra toughness. Its slower curing time allows it to bond tightly to concrete, filling in small cracks and imperfections for a more resilient surface.

Debunking the Myths:

- Curing Time: Some believe Epoxy’s longer curing time is a disadvantage. However, 24-48 hours of curing allows for deeper penetration and a stronger bond, unlike Polyurea’s fast cure, which can be prone to adhesion failures.

- UV Susceptibility: Epoxy can yellow when exposed to UV light, but this issue is easily mitigated when it’s sealed with a Polyaspartic topcoat.

4. Polyurea: Fast Curing, but Is It Worth it?

Polyurea is a fast-curing elastomer that promises quick installations. While it’s flexible and cures within hours, its weaker adhesion and higher costs raise questions about its long-term value.

Benefits of Polyurea:

- Flexibility: Polyurea can expand and contract with temperature changes without cracking, making it suitable for environments where temperatures fluctuate.

- Quick Curing: Polyurea cures in just a few hours, allowing for same-day project completion.

The Downside:

- Weaker Adhesion: Polyurea doesn’t bond as strongly to concrete as Epoxy, which can lead to peeling or delamination in high-traffic areas.

- Higher Cost: Polyurea is more expensive than Epoxy and may require additional base coats to achieve the same durability.

5. Polyaspartic: The Best Choice for a Long Lasting Topcoat

Polyaspartic is a type of aliphatic polyurea that offers a unique combination of durability, UV stability, and quick curing times. It’s a superior topcoat that is often used to protect an Epoxy base.

Why Polyaspartic Stands Out:

- Exceptional UV Stability: Polyaspartic doesn’t yellow when exposed to sunlight, making it ideal for outdoor spaces like patios, walkways, and driveways.

- Superior Durability: It resists abrasions and chemicals and impacts better than Epoxy or Polyurea.

- Fast Curing: It cures as quickly as Polyurea but with better adhesion and long-term protection.

Customizable Finishes:

Polyaspartic can be clear or pigmented, giving you aesthetic flexibility. Its high-gloss finish or custom colors make it an excellent choice for high-end garages or commercial spaces.

6. Epoxy vs. Polyurea vs. Polyaspartic: A Side-by-Side Comparison

Compare Durability, Cost, and Lifespan

Use this comparative table to highlight the differences between the three materials:

Property

- Curing Time

- Durability

- Concrete Adhesion

- UV Resistance

- Cost

- Flexibility

- Best Use

Epoxy

- 24-48 Hrs

- High

- Superior

- Poor (w/o topcoat)

- $$

- Low

- Base coat

Polyurea

- 1-2 Hrs

- Medium

- Moderate

- High

- $$$

- High

- Quick Installations

Polyaspartic

- 2-4 Hrs

- Very High

- Good

- Very High

- $$$$

- Moderate

- Top coat

Best Application for Each Material:

Epoxy

- Best For: Base coats in garages, industrial floors, and commercial spaces requiring maximum strength and durability.

Polyurea

- Best For: Fast turnarounds in exterior surfaces, such as parking lots for industrial coatings, where quick curing is a priority.

Polyaspartic

- Best For: Topcoats in areas exposed to UV light, such as patios, driveways, and commercial spaces, where appearance and long-term durability are essential.

7. How to Choose the Right Coating Based on Your Specific Project Needs

Make an Informed Decision Based on Your Needs

When selecting the best concrete floor coating, it’s crucial to focus on long-term durability, adhesion, and overall performance rather than just speed. Polyurea may be marketed for its rapid curing time, but there are better options available that provide superior protection and longevity. Here’s why epoxy and polyaspartic coatings are the ideal choices for a variety of concrete flooring applications.

When to Choose Epoxy

Epoxy coatings are the gold standard for applications requiring maximum adhesion and long-lasting durability. Here are some examples of when epoxy is the best choice:

- Heavy Traffic Areas: In industrial environments, warehouses, or even residential garages that see a lot of foot or vehicle traffic, epoxy excels due to its exceptional adhesion to concrete.

- Workshops and Garages: If you need a coating that withstands regular use of heavy equipment, tool drops, and chemical exposure, epoxy provides a cost-effective and reliable solution.

- Long-Term Value: While epoxy may take longer to cure than some other materials, this curing time allows it to bond more deeply with the substrate, resulting in a tough, resilient foundation that outlasts faster-curing alternatives like polyurea.

Why We Don’t Recommend Polyurea

While polyurea coatings are often promoted for their speed of installation, this quick cure time frequently comes at the cost of quality and durability. Here’s why we avoid recommending polyurea:

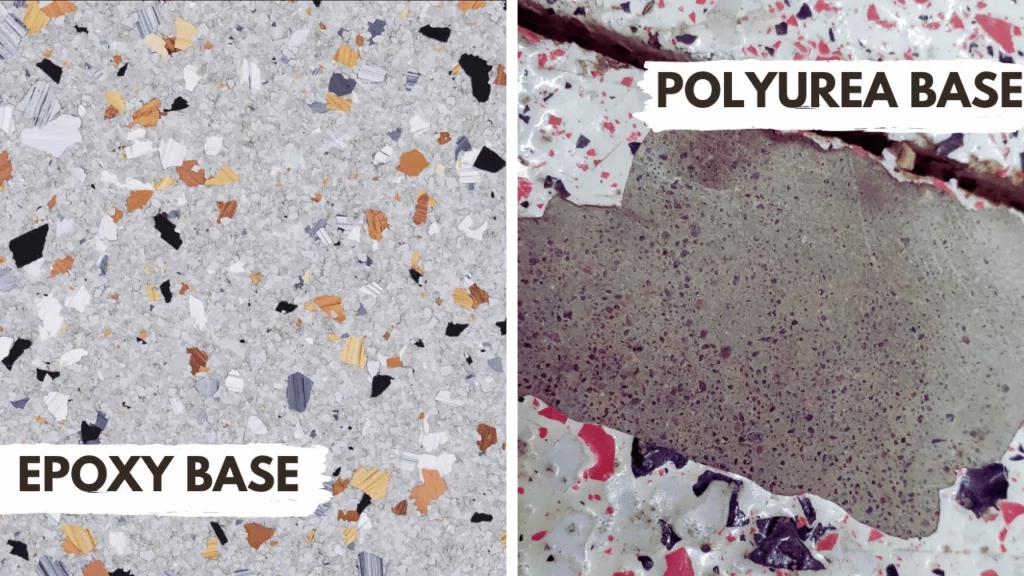

- Inferior Adhesion: Polyurea does not bond as effectively to concrete as epoxy. The rapid curing time leaves little margin for error in the application, increasing the likelihood of peeling, delamination, or failure under pressure.

- Shorter Lifespan: Polyurea may initially seem like a convenient option for its speed, but its overall lifespan tends to be shorter than coatings that use an epoxy base. This leads to higher long-term costs for maintenance and reapplication, offsetting any savings from its quick installation.

- Limited Versatility: Polyurea’s flexibility and fast cure time may make it a tempting choice for specific niche applications, but when it comes to high-traffic areas like garages, workshops, or commercial spaces, it often underperforms in comparison to epoxy and polyaspartic systems.

The Polyaspartic Advantage

When it comes to topcoats, polyaspartic coatings offer a superior blend of strength, aesthetics, and UV protection that other topcoats can’t match:

- UV Resistance: Polyaspartic coatings don’t yellow under sunlight, which makes them the perfect choice for indoor and outdoor applications, such as patios, walkways, and pool decks.

- Quick Curing without Compromise: While polyurea is fast curing, polyaspartic achieves quick turnaround times without sacrificing durability. It offers excellent protection against abrasions, chemicals, and impacts, making it ideal for high-traffic environments.

- Aesthetic Versatility: From high gloss finishes to customizable colors, polyaspartic topcoats allow for endless design possibilities while still providing a robust protective layer.

8. Our Hybrid System: Why Combining Epoxy and Polyaspartic is the Best Choice

When it comes to floor coatings, no single material can do it all. That’s why our hybrid system, combining epoxy as the base coat and polyaspartic as the topcoat, provides the most comprehensive solution for durability, flexibility, and UV protection. Let’s explore why this combination outperforms stand-alone coatings like polyurea or polyaspartic-only systems.

The Strength of Epoxy as a Base Coat

Epoxy is unbeatable when it comes to concrete adhesion. It penetrates deep into the concrete surface, creating a strong bond that ensures your floor won’t peel, crack, or delaminate under pressure. This deep bonding ability makes it the ideal foundation layer for any high-traffic or industrial space.

- Deep Concrete Bonding: Epoxy bonds at a molecular level with concrete, filling in micro-cracks for a smoother and more resilient surface.

- Long-Term Durability: Epoxy can withstand high-impact loads and heavy machinery without showing signs of wear.

The Flexibility and UV Protection of Polyaspartic

While epoxy excels at adhesion and durability, polyaspartic offers enhanced UV resistance, chemical resistance, and the ability to cure quickly, making it the perfect topcoat. When combined with epoxy, polyaspartic ensures that your floors not only last longer but also look better over time.

- UV Stability: Polyaspartic topcoats are highly resistant to yellowing and fading due to sunlight exposure, making them ideal for outdoor surfaces.

- Quick Curing: Unlike traditional coatings, polyaspartic topcoats cure in just 2-4 hours, allowing for faster project completion with no compromise in strength.

- Abrasion and Chemical Resistance: Polyaspartic protects the epoxy base coat from chemical spills, abrasions, and even harsh cleaning agents, making it suitable for both residential and industrial applications.

The Best of Both Worlds

By combining epoxy and polyaspartic, you create a hybrid flooring system that leverages the strengths of both materials. This system excels in high-traffic areas like garages, workshops, and commercial spaces. It provides the adhesion, strength, and durability of epoxy with the flexibility and UV stability of polyaspartic.

- Longevity: The hybrid system lasts significantly longer than polyurea alone, withstanding wear and tear for 10-20 years.

- Lower Maintenance: With this system, you’ll spend less time and money on repairs and upkeep, as the polyaspartic topcoat prevents discoloration, fading, and surface damage.

9. What Competitors Might Not Tell You

In a market crowded with options, it’s easy to get lost in flashy marketing claims about polyurea’s quick curing or promises of “same-day installations.” But not all floor coatings are created equal, and there are a few critical details that competitors might overlook over to make their product “seem” like the best solution. Here’s what you should be aware of.

Overemphasis on Speed

One of the primary selling points for polyurea coatings is their fast curing time, allowing installations to be completed in a single day. But while this speed might sound appealing, it often comes at the cost of long-term durability.

- Quick Curing vs. Proper Bonding: Polyurea’s rapid curing can leave less time for the coating to bond properly with the concrete. Over time, this can lead to improper coating, peeling, cracking, and delamination, especially in high-traffic areas.

- Epoxy’s Advantage: Although epoxy takes longer to cure, its slower curing process allows it to penetrate and bond more effectively with the concrete, providing a solid foundation for years to come.

Hidden Costs

Polyurea coatings might appear to be cost-effective at first glance, but hidden costs often emerge later in the form of maintenance, reapplications, and repairs.

- Shorter Lifespan: Due to its weaker adhesion and susceptibility to peeling, polyurea may require reapplication every 5-7 years, especially in high-use environments. This adds to the long-term cost of maintaining the floor.

- Reapplication and Repairs: Customers who opt for polyurea often find themselves having to deal with reapplications or repair work sooner than expected, negating the initial savings on installation costs.

Marketing Myths

Some competitors tout polyurea as a one-size-fits-all solution, marketing it as the superior option for any application. But while it has its place, polyurea often falls short when compared to hybrid systems or more tailored solutions.

- Myth: Flexibility Means Durability: Polyurea’s flexibility is often presented as a reason it’s more durable. However, flexibility alone doesn’t guarantee long-lasting protection. Epoxy’s superior adhesion provides the durability needed for long-term use, especially in areas that endure heavy traffic.

- Myth: UV Resistance Equals Total Protection: While polyurea and polyaspartic offer excellent UV resistance, that’s not the only factor to consider. UV stability won’t help when the floor starts peeling or cracking if your base coat doesn’t bond well to the concrete.

10. FAQs: Everything You Need to Know About Epoxy, Polyurea, and Polyaspartic

Choosing the right floor coating system can lead to several questions, especially when comparing epoxy, polyurea, and polyaspartic coatings. Here are some of the most frequently asked questions by customers when making this decision.

Polyurea has a fast curing time, which makes it appealing for quick projects. But epoxy provides better adhesion and long-term durability. If you want a coating that lasts and resists wear, epoxy is the better choice for the base.

Polyaspartic is fantastic for protecting your floor from UV rays and chemicals. But it cures too quickly to bond deeply with concrete. That’s why we use epoxy as the base and polyaspartic as the topcoat, ensuring a strong foundation and a beautiful, protective finish.

Epoxy and polyaspartic coatings can last 10-20 years or more with proper maintenance. Polyurea, while quicker to install, generally has a shorter lifespan and may need reapplication within 5-10 years, especially in high-traffic areas.

This combination offers the best of both worlds: epoxy’s strong adhesion creates a durable foundation, while polyaspartic’s UV resistance and chemical protection provide a long-lasting, attractive finish.

While some DIY kits are available, we highly recommend professional installation. The quick curing time of polyurea and polyaspartic leaves little room for error, and improper application can lead to peeling, bubbles, and uneven surfaces.

11. Maintaining Your New Floor Coatings: Best Practices For Long-Term Durability

After investing in high-quality epoxy and polyaspartic coatings, it’s important to follow a few simple maintenance steps to keep your floor looking pristine and performing optimally. Proper care will maximize its lifespan, prevent damage, and maintain that showroom-quality finish.

1.) Regular Cleaning Routine

- Sweep or Vacuum Frequently: Dirt, dust, and small debris can scratch the concrete surface of your floor if left unattended. A simple sweep and/or vacuum once or twice a week will keep your floor free from abrasive particles.

- Use pH-Neutral Cleaners: For a deeper clean, mop the floor with warm water and a pH-neutral cleaner. Harsh chemicals like ammonia or bleach can deteriorate the coating over time, so it’s best to stick with mild, floor-safe detergents.

- Avoid Standing Water: While your coating is highly resistant to moisture, it’s still a good practice to wipe up any standing water to avoid slipping hazards and ensure no water seeps into any cracks or unsealed edges.

2.) Preventing Surface Damage

- Use Protective Mats: For high-traffic areas or places where heavy machinery is used (e.g., garages or workshops), placing rubber mats or protective padding will help prevent scratches and scuffs caused by dropped tools or heavy equipment.

- Avoid Abrasive Cleaners and Brushes: Stick to soft brushes, microfiber mops, or brooms for cleaning. Harsh scrubbing pads or stiff bristles can dull the floor’s finish and cause micro-abrasions over time.

3.) Spot Cleaning Spills Promptly

- Oil and Chemical Spills: Epoxy and polyaspartic coatings are highly resistant to chemicals, but it’s still essential to clean up spills as soon as they happen. Oils, gasoline, or other chemicals left on the surface too long may cause staining or degrade the finish.

- Quick Wipe-Ups: For minor spills, a soft cloth and a gentle cleaning solution will do the trick. Ensure that no residue is left behind, as prolonged exposure to certain chemicals may cause discoloration.

4.) Seasonal Care

- Winter Maintenance: If your coated floors are in a garage or exterior area, road salts and de-icing chemicals from car tires can be abrasive. Rinsing the floor occasionally during the winter months will help prevent the buildup of these materials and protect the surface.

- Temperature Control: Extreme temperature changes won’t affect your polyaspartic topcoat, but maintaining a stable environment helps preserve the longevity of the coating.

5.) Reapplying Top Coats When Necessary

- Inspect Annually: Though epoxy and polyaspartic coatings are known for their durability, it’s a good idea to inspect your floors yearly for any signs of wear. If you notice dullness, loss of shine, or light abrasions, you may consider reapplying a polyaspartic topcoat to restore the finish.

- Professional Maintenance: For heavily trafficked areas or commercial spaces, scheduling professional maintenance every few years ensures your floor remains in top condition.

Key Takeaways:

- Regular cleaning and spot treatment keep your floor looking new and prevent minor issues from becoming big problems.

- Avoid abrasive tools and cleaners to maintain the smooth, polished finish.

- Address spills quickly to protect the surface, even though your coating is chemical-resistant.

- Inspect your floors annually and consider professional touch-ups when necessary for high-traffic areas.

By following these simple guidelines, your epoxy and polyaspartic floors will retain their durability and aesthetic appeal for years to come.

12. The Clear Winner for Long-Term Durability

When it comes to choosing the best floor coating for your concrete, it’s easy to get lost in marketing hype around fast cures and flashy promises. But if you want a floor coating that lasts, you need a system that combines epoxy’s deep adhesion with polyaspartic’s UV resistance and fast curing.

Here's The Bottom Line...

- Epoxy provides unmatched adhesion, bonding tightly to your concrete and creating a rock-solid foundation that resists peeling, cracking, and delamination.

- Polyaspartic offers superior UV protection, faster curing, and a high-gloss finish that stays vibrant—even in outdoor settings.

This hybrid system isn’t just a quick fix; it’s a long-term investment that saves you money on repairs and maintenance while keeping your floors looking pristine for years to come.

Ready to Transform Your Floors?

If you’re looking for durability, reliability, and aesthetic appeal in your floor coatings, epoxy and polyaspartic are the ultimate combo. Want to see how this system can elevate your space?

Here’s what to do next:

- Contact Us at +1 (214) 471-6134 for a free consultation. Our team of floor coating experts are ready to walk you through the best options for your project.

- Get a Custom Quote tailored to your needs—whether it’s for your garage, commercial space, or outdoor area.

Looking to transform more than just your floor? Check out our Garage Floor Coating, Commercial Coatings, Patio Coatings, and Walkway Coatings services to see how we can help bring your vision to life.

Don’t settle for short-term solutions. Invest in a floor that lasts. Reach out today, and let’s get started on creating a stunning, durable floor that will stand the test of time.

Ready to get started? Contact us today for a free, no-obligation consultation and see why epoxy and polyaspartic are the best choices for your next floor coating project. Let’s create something that lasts!